Lindstrom Precision tools

Good performing cutter for general repair and fine mechanical work.

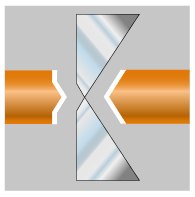

Most of the cutters have a specially made box joint with extra long contact surfaces, made possible by special manufacturing techniques. Undesirable joint movement is held to a minimum, ensuring extremely precise alignment of the jaws, even at the extreme tip.

80 Series cutters

This range of cutters offers unsurpassed cutting capacity covering a wide range of wire dimensions and types.

1% Carbon / Chrome Ball Bearing Grade Steel

Material usually reserved for high stress applications provides incredible impact resistance and resiliency with smoother, cleaner penetration at cutting edge.

63 - 65HRC on Cutting Edges

Precision induction hardening of 1% Carbon / Chrome Ball Bearing Steel allows high rockwell hardness without brittleness resulting in longer lasting tool.

CNC Grinding of Forged Blanks

Computer controlled machine grinding guarantees edge angle accuracy and contact which increases tool reliability and consistency.

Forged Components

Grain structure follows profile of the blank to maximise tool strength.

Available cuts and size chart

Ultra - flush

Unique Ultra - Flush cutters leave a flat surface on cut leads which is considered to be the ultimate in conformance to tough soldering and mechanical shock specifications.

The Flush cut

The cutting result of most “flush” cutters, their individual terminology notwithstanding, is somewhat similar. Flush cutters also “pinch” the leads, but at a lower altitude than Micro - Bevel cutters.

Micro bevel

Micro - Bevel cutters leave a minimal rise on cut leads resulting in a smaller overall surface soldering area.

8130 - Micro Bevel

Measurements: A (108 mm), B (8 mm), C (8 mm), D (5 mm), F (0.8 mm)

Capacity: 0.2 - 1.0 mm

Weight: 43 g

8131 - flush cut

Measurements: A (108 mm), B (8 mm), C (8 mm), D (5 mm), F (0.8 mm)

Capacity: 0.1 - 1.0 mm

Weight: 43 g

8132 - ultra flush cut

Measurements: A (108 mm), B (8 mm), C (8 mm), D (5 mm), F (0.8 mm)

Capacity: 0.1 - 1.8 mm

Weight: 44 g

8140 - Micro Bevel

Measurements: A (110 mm), B (10 mm), C (10 mm), D (6 mm), F (0.8 mm)

Capacity: 0.12 - 1.25 mm

Weight: 46 g

8141 - flush cut

Measurements: A (110 mm), B (10 mm), C (10 mm), D (6 mm), F (0.8 mm)

Capacity: 0.1 - 1.25 mm

Weight: 45 g

8142 - ultra flush cut

Measurements: A (110 mm), B (10 mm), C (10 mm), D (6 mm), F (0.8 mm)

Capacity: 0.1 - 1.0 mm

Weight: 46 g

8150 - Micro Bevel

Measurements: A (112.5 mm), B (12.5 mm), C (12.5 mm), D (6 mm), F (1.2 mm)

Capacity: 0.3 - 1.6 mm

Weight: 50 g

8151 - flush cut

Measurements: A (112.5 mm), B (12.5 mm), C (12.5 mm), D (6 mm), F (1.2 mm)

Capacity: 0.2 - 1.6 mm

Weight: 49 g

8152 - ultra flush cut

Measurements: A (112.5 mm), B (12.5 mm), C (12.5 mm), D (6 mm), F (1.2 mm)

Capacity: 0.2 - 1.25 mm

Weight: 49 g

8160 - Micro Bevel

Measurements: A (125 mm), B (16 mm), C (16 mm), D (8 mm), F (1.6 mm)

Capacity: 0.4 - 2.0 mm

Weight: 88 g

8160j - Micro Bevel

Measurements: A (125 mm), B (16 mm), C (16 mm), D (8 mm), F (1.6 mm)

Capacity: Max - 0.5 mm

Weight: 87 g

8161 - flush cut

Measurements: A (125 mm), B (16 mm), C (16 mm), D (8 mm), F (1.6 mm)

Capacity: 0.3 - 2.0 mm

Weight: 88 g

8162 - ultra flush cut

Measurements: A (125 mm), B (16 mm), C (16 mm), D (8 mm), F (1.6 mm)

Capacity: 0.3 - 2.0 mm

Weight: 88 g